- Finance

-

Equipment

- Beverage

- Coffee

-

Cooking

- Shop all cooking

- Bratt pans

- Char grills

- Chicken rotisseries

- Combi ovens

- Contact grills

- Convection ovens

- Conveyor toasters

- Cooktops

- Cooktop oven combos

- Crepe and pancake makers

- Deck ovens

- Fryers and oil filters

- Griddles

- Kebab machines

- Microwaves

- Pasta cookers

- Pizza ovens

- Range ovens

- Rice cookers

- Salamander grills

- Sous vide

- Speed ovens

- Steamers

- Tandoor ovens

- Toaster grills

- Waffle makers

- Wok burners

- Other

- Dishwashers

- Food display

- Food preparation

- Stainless steel

- Laundry

- Point of sale

-

Refrigeration

- Shop all refrigeration

- Blast chillers

- Chest freezers

- Countertop fridges

- Display freezers

- Display fridges

- Gelato freezers

- Ice-cream machines

- Ice machines

- Pizza prep fridges

- Refrigerated drawers

- Sandwich prep fridges

- Slushie machines

- Under counter freezers

- Under counter fridges

- Upright freezers

- Upright fridges

- Other

- Restaurant furniture

- Shop all equipment

- Customers

- FAQs

- Resources

- About Us

Share

Best commercial meat mincer: Buyer’s guide

article

What our commercial meat mincer guide covers

- Introduction

- Types of commercial meat mincers

- Styles of commercial meat mincers

- Main things to consider when choosing a commercial meat mincer

- Best commercial meat mincers in Australia

- Used commercial meat mincers — worth considering?

- Warranty & insurance

- Questions to ask when shopping for a commercial meat mincer

- Commercial meat mincer — Frequently asked questions

- Commercial meat mincer terminology

- How to maintain your commercial meat mincer

- How often should your commercial meat mincer be serviced?

Commercial mincers, also known as meat grinders, are essential equipment for restaurants, butchers, and other foodservice establishments that handle large quantities of meat.

These machines can grind meat into different textures and sizes, making them ideal for making sausages, hamburgers, and other ground meat products.

Mincing meat in-house is generally cheaper than buying pre-minced meat and some commercial mincers allow you to add seasonings to your mince.

When purchasing a commercial mincer, there are several factors to consider; this buyer’s guides explains them in detail, so you can make an informed decision on the best commercial mincer for your needs.

Types of commercial meat mincers

Manual meat mincers

Used for processing relatively small quantities of meat, manual meat grinders are typically clamped to the edge of a table and hand-cranked.

At best, they can produce about a kilogram of minced meat per minute.

Also, depending on the person using it, it has limited power.

The mechanism features multiple cutting plates rotating against a cutting knife to produce minced meat ranging from 3/16th of an inch to half an inch in bit sizes.

Best for

Commercial kitchens that need small quantities of artisan, speciality or customised minced food products.

Electric meat mincers

Most commercial meat mincers are electric.

They are essential in commercial settings like restaurant kitchens, butcher shops and delis, where demand for minced meat is high.

More sophisticated than manual mincers, electric mincers feature different-sized cutting plates and food-pushing tools and come with accessories like sausage-extrusion tubes.

Styles of commercial meat mincer

Meat mincers range in size from small, countertop units to large, high-output floor-mounted ones (also known as industrial mincers).

Most restaurants and cafes use tabletop commercial meat mincers.

In delis and food processing factories where minced meat is required quickly and in large volumes, industrial mincers are used.

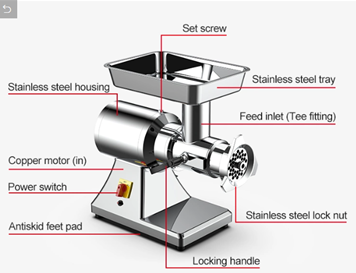

Parts of a commercial meat mincer

Motor

The higher the motor’s horsepower, the more efficiently it minces meat, including tougher meat like meat with a high sinew level.

Meat tray

This is where you place strips or cubes of meat before putting them into the feeding tube for mincing.

Feeding tube

The part of the mincer through which the meat travels before it gets minced.

The feeding tube’s diameter is proportionate to the mincer's capacity.

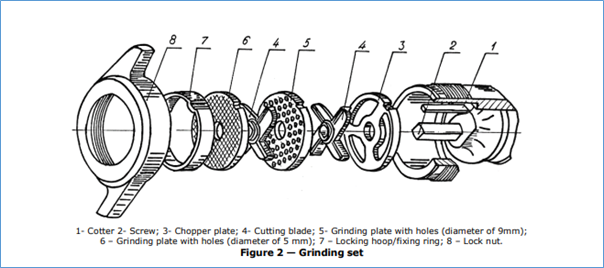

Cutting

This is the part that gets the actual mincing done.

It’s a star-shaped metal blade that spins ferociously and minces the meat.

Grinding plate

It is a flat circular plate with holes in it.

The size of the plate’s holes determines the consistency of the mince.

A mincer can have more than one grinding plate with different hole diameters.

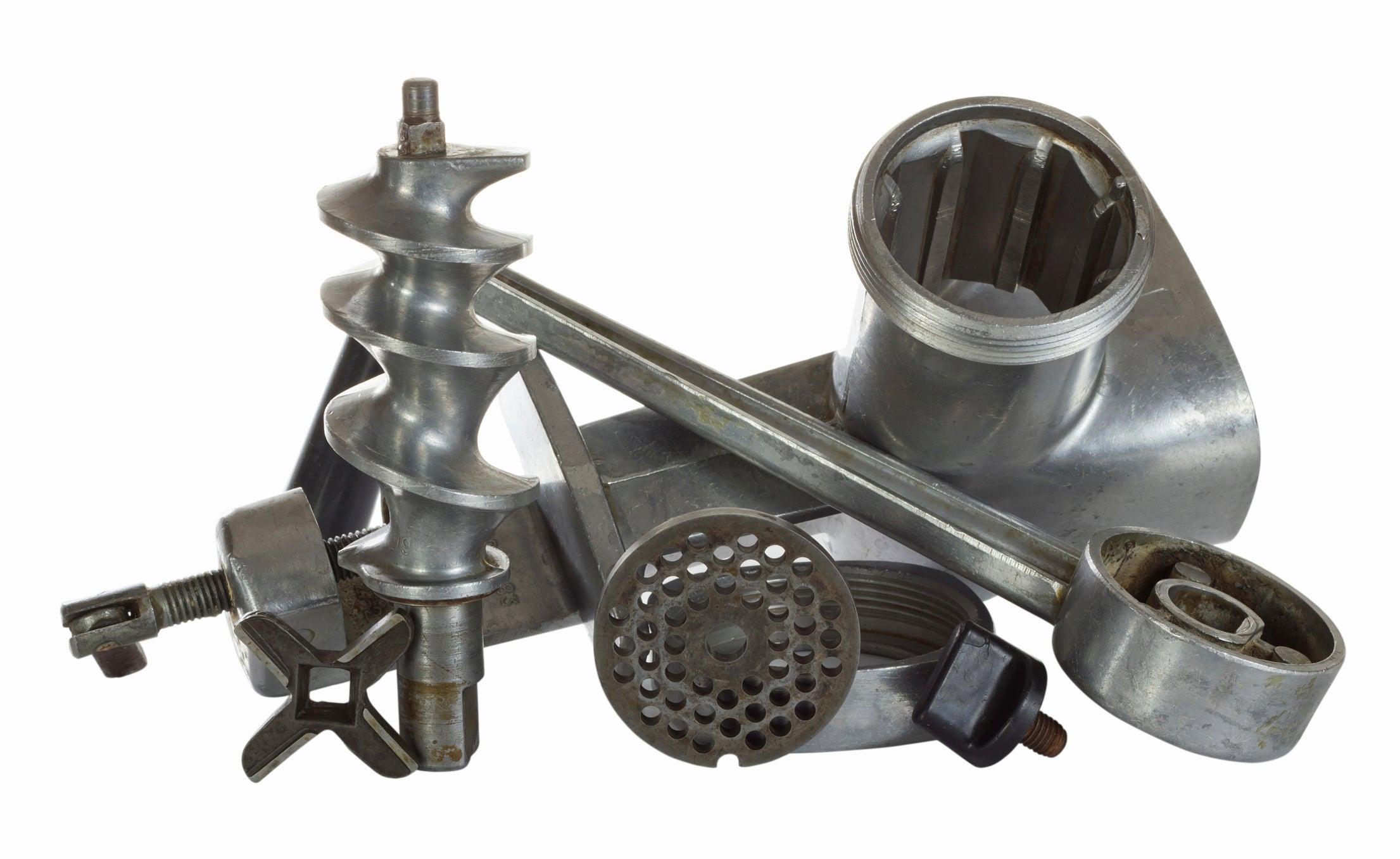

Auger

The horizontal screw conveyor — the part that moves the meat towards the cutting blade and grinding plates — is known as the auger.

It’s also known as the worm or screw.

Plunger or meat push

This is used to push the meat through the feeding tube and towards the auger.

Meat tends to get stuck in the tube, so a little push. helps.

Main things to consider when ordering a commercial mincer

Along with the type and style of mincer, here are some of the things you should factor in when choosing a commercial mincer:

What type of food will you be mincing?

Many foods items, along with meat, can be minced in a commercial meat mincer.

As well as beef, pork, chicken and veal, for example, mincers can finely grind vegetables such as onions, peppers, garlic, tomatoes, and more.

Heavy-duty electric mincers are better suited to grinding heavier meats, including bones.

How much do you need to mince?

The amount of minced meat businesses need varies.

For instance, a deli will likely need more mince than, say, a pizzeria.

So, it’s important to match the mincer’s output to your business’s requirements.

Grinding plates

The consistency of the mince required depends on the type of food being prepared.

Most meat grinders come with several sizes of grinding plates, or dies, with varying-sized holes through which the meat is pushed out.

The size of the holes determines the consistency of the mince.

By understanding the type of mince needed, you can select the mincer with the right-sized grinding plates.

If you’re mincing the meat finely, it’s best to start with the largest hole first and re-grind the meat through successively smaller grinding plates.

Here are some guidelines:

19mm: Very coarse

Good for the first grind, and dishes like casserole, chili or stew.

13mm: Very coarse

Good for the first grind, and dishes like casserole, chilli or stew.

5mm: Coarse

Good for the first grind, and dishes like meatloaf, meatballs, hamburgers or Italian sausages.

4mm to 8mm: Coarse

Good for dishes like tacos, spaghetti Bolognese or kebabs.

4mm to 4.8mm: Medium

Good for dishes like hamburger patties, meatballs, Bolognese sauce or Empanadas.

3mm to 3mm: Fine

Good for dishes like breakfast sausages, hot dogs, Italian meatballs or dumplings.

Size/ capacity & output of the meat mincer

The output of a commercial meat mincer (kilograms per hour) depends largely on its size.

The size of commercial meat mincers is based on the diameter of its grinder plate.

While there are some variations between manufacturers, the size numbering system is generally consistent across most commercial grinders.

The higher a mincer’s number, the bigger its motor and hopper/loading tray, the more powerfully it grinds, and the more mince it churns out each hour.

The following are some of the most common commercial mincer sizes and their corresponding numbers:

|

Mincer size |

Mincing plate diameter (mm) |

Cutting blade (mm) |

Cutting blade hole size

|

|

#5 |

54 |

48 |

6.4 |

|

#8 |

64 |

54 |

9.5 |

|

#12 |

70 |

60 |

11 |

|

#22 |

83 |

73 |

12.7 |

|

#32 |

98 |

54 |

16 |

|

#42 |

129 |

117 |

22 |

Motor power

Different meats have varying levels of hardness and juiciness.

Choosing a mincer with enough grinding power for the type of meat is thus important.

Among other things, it will help prevent jamming.

The higher the wattage of the meat mincer, the more powerful it is and the more efficiently it can process meat.

For hard meats like beef and pork, a motor with a power rating of 1600 watts (W) or more works best.

For tender meats such as chicken and turkey, a motor with less than 1600W will suffice.

If the meat is particularly juicy, then an 800W motor will get the job done.

For dry meats, you’ll need more power.

If you’ll be using the mincer a lot and processing large amounts of meat, you’ll need a suitably powerful mincer.

A motor with more mincing power can easily handle bigger bones and churn out larger batches quicker.

Safety features

Mincing meat puts a fair amount of stress on the mincer, which can overheat or jam.

The following features help protect the machine and keep the user safe too:

Auto shut-off

The motor switches off automatically when the mincer jams or is overloaded.

Non-slip feet/ base

These help absorb vibrations and keep the mincer from moving or sliding during operation.

Overheat protection

If a mincer gets too hot, this feature will automatically shut it off.

Emergency stop

Engaging this switch will cause the mincer to shut off instantly.

The standard stop works just fine, but for heavier mincers a clearly marked and easily accessible emergency stop button is provided.

Ease of use

There are many features on a mincer that make it easier to use.

Here are some of them:

Feeding tube

A feeding tube with a sizeable diameter will allow for a good quantity of meat to be pushed into the mincer.

The wider the tube, the easier it will be for you to use the plunger to dislodge meat stuck in the tube.

Variable speed settings

A mincer with variable speed settings gives the user more control, enabling them to choose the optimal speed for the type of meat or vegetable being minced.

Plunger or meat pusher

Model-specific plungers or meat pushers are important as they help dislodge or push more meat into the feeding tube.

Reversible function

Too much meat in the auger may cause the mincer to jam.

Engaging the reverse function makes the auger move in the opposite direction.

This helps dislodge any stuck meat and unclog the mechanism.

Accessories

External attachments like sausage extrusion tubes make the mincer more versatile.

Ease of cleaning

A commercial mincer must be easy to clean.

Look out for the following helpful features:

Dishwasher-safe parts

Most commercial mincers have dishwasher-safe parts such as the auger, tee joint, and cutting blade.

Detachable components

Commercial mincers can be easily dismantled and reassembled.

Dismantling a mincer ensures each part is properly cleaned.

Sturdy construction

Mincing meat can be messy.

A stainless-steel housing provides an easy-to-clean surface that is also non-corrosive.

Smooth design

A mincer with a smooth surface will have fewer areas where grime and debris can collect, making it easier to clean.

Budget

The price of a light-duty commercial mincer is around $1000 (e.g. the Reber #12 electric meat mincer ) while heavy-duty meat mincer (like the RFE DM 32 ) will set you back around $5,000.

As the size of the mincer increases, so does the price.

As well as the cost of the mincer, you’ll also need to budget for transport, installation, maintenance and repairs.

For example, the cost of regularly sharpening the cutting blade.

Construction material

Meat mincers need to be sturdy and built of materials that resist corrosion.

So, look for a meat grinder that has a stainless-steel and anodised-aluminium construction (which most of them have).

Not only is stainless steel durable, it’s also dishwasher-safe and easy to clean.

Hopper/ loading tray volume

The bigger the hopper or loading tray, the more meat can be loaded into the mincer..

Best commercial meat mincers in Australia

While there is a numerous makes of commercial meat mincers available in Australia, we’ve rounded up a handful of the leading ones:

Brice

Brice was established in 1939, and for a while was the only Australian manufacturer of electric slicers, mixers, and potato peelers.

Today, Brice Australia distributes and services food machinery made by some of the world’s leading brands.

The company remains 100% Australian-owned and operated, and its post-sales services are legendary.

Brice distributes two series of commercial meat mincer machines: the LNKDM and the OMATS series.

LNKDM bench top meat mincers

Best suited for restaurants, catering kitchens, butchers and pizzerias, the LNKDM series is known for being quiet and efficient.

It comprises two heavy-duty mincer models — the DM12 and DM22.

The machines are made of stainless steel and anodised aluminium.

The throat inlet, cutting gears and barrel are made of stainless steel.

For maximum lubrication, the drive-reduction gears are run in an oil bath.

|

Key features: |

|

|

|

· Construction: |

Stainless steel and anodised aluminium |

Stainless steel and anodised aluminium |

|

· Power: |

550 W |

750 W |

|

· Throughput (Kg/hr): |

120 |

250 |

|

· Drive reduction gears in oil bath: |

Yes |

Yes |

|

· Reversing switch: |

Yes |

Yes |

|

· Weight (Kg): |

26 |

33 |

|

· Pusher included: |

Yes |

Yes |

|

· Removable barrel: |

Yes |

Yes |

|

approved: |

Yes |

Yes |

|

· Size |

429 x 382 x 405 |

479 x 420 x 416 |

OMATS series meat mincers

Best suited for large restaurants, catering kitchens, butchers and pizzerias, the OMATS series comprises three industrial meat mincer models — the TS12, TS22, and TS32.

These Italian-made mincers are quiet and efficient and produce a variety of minces, including for sausages.

Their construction is the same as the LNKDM series, however their throughput is bigger and they can be supplied with three-phase power.

|

Key features: |

TS 12 |

TS 22 |

TS 32 |

|

· Construction: |

Stainless steel and anodised aluminium |

Stainless steel and anodised aluminium |

Stainless steel and anodised aluminium |

|

|

|

|

|

|

· Power: |

750 W |

110 W |

1800 W |

|

· Throughput (Kg/hr): |

178 |

350 |

500 |

|

· Drive reduction gears in oil bath: |

Yes |

Yes |

Yes |

|

· Reversing switch: |

Yes |

Yes |

Yes |

|

· Cutting blade groups available |

No |

Yes, 3 blade group |

Yes, 3 blade group |

|

· Weight (Kg): |

22 |

32 |

68 |

|

· Pusher included: |

Yes |

Yes |

Yes |

|

· Receiving tray included: |

Yes |

Yes |

No |

|

· CE approved: |

Yes |

Yes |

Yes |

|

|

33 |

33 |

33 |

|

· Size |

220 x 490 x 430 |

230 x 670 x 470 |

270 x 440 x 600 |

Hobart

Built for on-demand meat mincing, Hobart’s mincers are generally on the heavy-duty end of the scale.

The 4812-36 is powerful, fast and efficient, producing mince that is always uniform in consistency.

All the parts that come into contact with the meat can be easily removed for cleaning — without using tools.

Key features:

- Construction: Stainless steel housing and trim

- Horsepower: ½ HP

- 3.6kg to 4.5kg per minute

- RPM: 174

- Reversing switch: Yes

- Phase: 1

- Plate size: #12

- Weight: 39kg (shipping weight)

- Size (WxDxH mm): 325 x 610 x 591

- Legs: 4-inch standard size with stainless-steel casing

Hobart 4822-34

The big brother of the previous model, the Hobart 4822-34 #22 meat mincer features a more powerful motor.

The mincer is fast and produces mince with even consistency, every time.

All the parts that come into contact with the meat can be easily removed for cleaning — without using tools.

Key features:

- Construction: Stainless-steel housing and trim

- Horsepower: 1½ HP

- Throughput: 5.5kg to 9kg per minute

- RPM: 212

- Reversing switch: Yes

- Phase: 1

- Plate size: #12

- Weight: 48kg (shipping weight)

- Size (WxDxH mm): 325 x 759 x 591

- Legs: 4in standard size with stainless steel casing.

Wedderburn

Founded in 1896, Wedderburn is a100% Australian, family-owned business that makes food equipment and POS systems, among other things.

Wedderburn’s meat mincers are built for heavy-duty usage.

Wedderburn WFM22BSA

This bench-top mincer from Wedderburn is their base model.

Best for kitchens, hotels, supermarkets, delis and the meat industry, this easy-to-clean mincer can be dismantled without any special tools for cleaning.

Key features:

- Construction: Stainless steel

- Horsepower: 1.5 HP

- Power: 1.1kW

- Electrical load: 10 Amp single phase

- Throughput: Up to 300kg/h

- Feeding-tube width: 56mm

- Reversing switch: Yes

- Hopper capacity: 3kg-6kg

- Cutting blade hole size: 4.5mm

- Weight: 39kg

- Overall size (WxDxH mm): 450 x 300 x 360.

Wedderburn WFM32BSA

The next model up, the WFM32BSA, has a much bigger throughput of 800kg/h and a wider feeding tube.

Like it’s smaller brother, it can be dismantled without special tools, making it easy to clean and sanitise.

Key features:

- Construction: Stainless steel

- Horsepower: 2.2 HP

- Power: 1.85kW

- Electrical load: 10 Amp single phase

- Throughput: Up to 800kg/h

- Feeding-tube width: 76mm

- Reversing switch: Yes

- Hopper capacity: 3kg-6kg

- hole size: 4.5mm and 8mm

- Weight: 47kg

- Overall size (WxDxH mm): 450 x 280 x 460.

RFE

Headquartered in New South Wales, RFE is a reputable commercial food equipment brand with a service network across Australia.

RFE DM12 mincer

The DM12 is a heavy-duty mincer.

Made of 304 stainless steel, it’s best suited to large supermarket chains.

This fan-cooled mincer features a removable barrel for easy cleaning.

Key features:

- Construction: Stainless steel

- Power: 550W

- Throughput: Up to 180kg/h

- Reversing switch: Yes

- hole size: 4.5mm & 6mm options

- Weight: 26kg

- Overall size (WxDxH mm): 400 x 409 x 382.

RFE DM22 mincer

The stainless steel, fan-cooled DM22 impresses with its capacity.

Key features:

- Construction: Stainless steel

- Power: 750W

- Throughput: Up to 350kg/h

- Reversing switch: Yes

- hole size: 4.5mm & 6mm options

- Weight: 33kg

- Overall size (WxDxH mm): 400 x 409 x 382.

Reber

Reber manufactures sausage fillers, tomato machines, and meat mincers, among other appliances.

Established in 1964, the Italian brand’s quality and service has improved in leaps and bounds.

One of the distinguishing features of Reber meat mincers are the numerous attachments that can be bolted onto a machine to make it multi-purpose.

Reber 9508 N.8 stainless steel pro

This Italian-made mincer’s body, auger, ring nut and even its encasing are all made of stainless steel.

It not only minces, it can also fill sausages. It’s 400W/0.3HP motor and oil-bathed gear system ensure it performs reliably.

Among its optional attachments are a tomato-puree extractor, cheese grater, 15mm, 20mm and 25mm funnels for filling sausages, and even a T-bar support for the sausage filling.

Key features:

- Construction: Stainless steel

- Power: 400W/0.3HP

- RPM: 104

- Throughput: 40kg–70kg/h

- Reversing switch: Yes

- hole size: 8mm

- Weight: 33kg

- Overall size (WxDxH mm): 480 x 220 x 310

- approved: Yes.

Reber N32 Mincer

This heavy-duty mincer’s body, auger, ring nut and casing are all made of stainless steel.

It features a 1200W/1.5HP motor and oil-bathed gears, which ensure the mincer performs smoothly over long periods.

The throughput is 100kg – 160kg/h.

Optional attachments include a tomato-puree extractor, cheese grater, 15mm, 20mm and 25mm - funnels for filling in sausages, and a T-bar support.

Key features:

- Construction: Stainless steel

- Power: 1200 watts

- Horsepower: 1.5HP

- RPM: 1380

- Throughput: 40kg–70kg/h

- Reversing switch: Yes

- hole size: 8mm

- Weight: 30kg

- Overall size (WxDxH mm): 600 x 320 x 320

- approved: Yes.

Used commercial meat mincers - worth considering?

Spending thousands of dollars on a new commercial meat mincer can put a strain your budget and cash flow.

If you’d prefer not to invest a lot of money in a commercial mincer, a cheaper, pre-owned appliance might be the solution you’re looking for.

SilverChef’s range of ‘Certified Used’ commercial equipment is mostly ex-rental equipment sourced from businesses we know and trust.

The equipment is typically less than two-and-a-half years old, has been fully refurbished by us, and is backed by a three-month parts-and-labour warranty.

You can either buy or finance the ‘Certified Used’ equipment (or clearance equipment) on our website.

We’re one of the few financiers, if not the only one, in Australia that funds second-hand commercial kitchen equipment.

Read more about ‘Certified Used’ equipment

Warranty & insurance

Most equipment manufacturers provide warranties ranging from one to five years, depending on the type of equipment.

If the equipment develops a covered fault within that time, the manufacturer is obliged to repair or replace the equipment or give you a full refund.

Carefully study the warranty to understand exactly what is and isn't covered.

SilverChef offers a three-month parts-and-labour warranty on all our ‘Certified Used’ and clearance equipment.

Business insurance covers loss or damage to your commercial kitchen equipment and other property.

This cover typically includes fire, accident, and theft. Some insurers also offer equipment-breakdown cover.

Contact your insurer to confirm whether the equipment you’re getting is automatically covered by your policy or will need to be added to it.

If your insurer doesn’t provide flood cover as standard, you may wish to consider requesting it.

Commercial meat mincer - frequently asked questions

These are a few FAQs that buyers tend to ask us before ordering:

Is it a good idea to freeze meat before mincing?

Frozen meat minces a lot better than room-temperature meat as the former is less flexible.

Meat must always be cut into chunks that fit into your mincer’s feeding tube.

Ideally, these chunks should be frozen for 15–20 minutes before feeding them in.

Avoid over-freezing the meat as it will damage the cutting blade and other mechanisms. For more details, read the user manual.

What’s the difference between a meat mincer and a meat grinder?

Meat mincers and meat grinders are one and the same thing.

‘Mincer’ is more commonly used in Australia and the UK, while ‘grinder’ is the popular term in the USA and Canada, for example.

What safety precautions need to be taken when operating a meat mincer?

Here are some tips for safely operating a meat mincer:

- Keep hair and sleeves pulled back while feeding the meat into the mincer.

- Never use your hands or fingers to push the meat through the feeding tube. Instead, use the meat plunger or pusher that was supplied with the machine.

- Always use a spatula, turner or knife to scrape meat from the output plate of the mincer.

- Don’t force meat through the feeding tube, which can jam the machine.

- Always unplug your grinder while storing it.

What else can you use a meat mincer for?

Aside from meat, many commercial meat mincers can mince vegetables like onions, capsicums and tomatoes, and cheese, among other things.

Your machine’s user manual should explain what else it can process besides meat.

How do you keep meat grinders from clogging?

At a minimum, you should make sure the meat chunks you put into the feeding tube are the right size and temperature and devoid of sinews.

Can you put bones through a mincer?

Yes — soft bones from poultry like duck, chicken and turkey can be minced in a meat mincer.

Hard bones, such as those in cattle and deer, are a no-no.

Your mincer’s user manual should tell you exact size of the bones it can mince.

How to clean a mincer?

Like any kitchen equipment, a commercial meat mincer and its parts must be cleaned regularly.

As well as giving the machine a wipe-down with a soft cloth and mild detergent when required throughout the day, at the end of the day you should:

- Switch off the mincer and dismantle it.

- As per the manufacturer’s manual, soak parts in warm-to-hot water with mild detergent.

- Scrub and wash the parts.

- Rinse and place the parts in a sanitiser solution for about two minutes.

- Remove the parts and let them air-dry.

- Wipe the parts down and check for any spots containing grease, oil or food debris.

- Assemble them as per the correct order and you’re good to go again.

Commercial meat mincer terminology

CE marking

CE, an acronym for the French term “Conformite Europeenne”, is used by the European Union (EU) to certify that a product meets the health, safety and environmental requirements appropriate for being sold within the European Economic Area (EEA).

IP rating

The Ingress Protection (IP) rating is an international standard for rating the degree of effectiveness of an electrical enclosure to safeguard the equipment’s internal parts from water, dust and other objects.

Reverse function

All meat mincers jam for one reason or another.

The mincer’s reverse function makes the motor run in reverse, helping unclog any stuck meat.

Sausage attachment

This accessory channels minced meat into sausage casings with ease.

Funnel-shaped and easy to attach, it’s also known as a sausage stuffer or extrusion tube.

Torque

This is a measure of the motor’s ability to turn the cutting blade when it meets resistance from the food to be minced.

A motor with higher torque will be able to mince meat a lot easier than one with lower torque.

Torque is critical if you’re looking for a mincer for tough food items like cuts of meat with high levels of sinew

Screw ring

The outer ring that screws onto the mincer after the mincing plate has been securely fixed.

It helps keep the plate and other mechanisms locked in well.

Be careful not to thread the ring and clean it regularly for optimum performance.

Throughput

The rate — kilograms per hour, or kg/h — at which a mincer can produce minced meat.

Speed control

The mincer feature that controls the rate at which the meat or other ingredients is minced.

How to maintain your commercial meat mincer

Regular maintenance of your mincer will increase its life and delay repair costs.

Here are a few basic maintenance tips:

- Feed the right size, quantity and temperature of meat chunks into the mincer.

- Remove as much sinew from the meat as you can to reduce the risk of clogging.

- If mincing the meat finely, start with a large mincing plate and re-grind the meat through successively smaller ones. In other words, don’t run the meat chunks directly through the smallest grid plate.

- Keep your cutting blade sharp.

- Make sure parts that require regular oiling are well-oiled. For instance, make sure to lubricate the oil seal of the gearbox through the screw hole every six months, depending on the model and frequency of use.

- Always switch off the machine at the end of the day, before beginning the daily cleaning process.

- Wipe down the mincer after each use.

How often should your commercial meat mincer be serviced?

The frequency of professional servicing for a commercial meat mincer varies, depending on its usage and the manufacturer's recommendations.

Generally, it is recommended you get the machine professionally serviced at least once a year to ensure that it operates efficiently and safely.

If you use your mincer frequently or for extended periods, it may require more frequent servicing, such as every six months.

Keep your cash, use ours!

Hospitality equipment can be expensive and paying for it outright can put pressure on your business’s cash flow.

Our finance solutions allow you to get the equipment you want now and to pay for it in small, regular amounts out of the revenue it generates for you.

Rent–Try–Buy® not only helps you maintain your cash flow, it also gives you unrivalled flexibility to adapt your equipment to the changing needs of your business.

You can upgrade or buy the equipment at any time or, after 12 months, return or continue renting it.

If you decide to buy the equipment, we’ll give you back 75% of the net rent you paid in the first year and 25% of any rental payments thereafter — to put toward the purchase price.