- Finance

-

Equipment

- Beverage

- Coffee

-

Cooking

- Shop all cooking

- Bratt pans

- Char grills

- Chicken rotisseries

- Combi ovens

- Contact grills

- Convection ovens

- Conveyor toasters

- Cooktops

- Cooktop oven combos

- Crepe and pancake makers

- Deck ovens

- Fryers and oil filters

- Griddles

- Kebab machines

- Microwaves

- Pasta cookers

- Pizza ovens

- Range ovens

- Rice cookers

- Salamander grills

- Sous vide

- Speed ovens

- Steamers

- Tandoor ovens

- Toaster grills

- Waffle makers

- Wok burners

- Other

- Dishwashers

- Food display

- Food preparation

- Stainless steel

- Laundry

- Point of sale

-

Refrigeration

- Shop all refrigeration

- Blast chillers

- Chest freezers

- Countertop fridges

- Display freezers

- Display fridges

- Gelato freezers

- Ice-cream machines

- Ice machines

- Pizza prep fridges

- Refrigerated drawers

- Sandwich prep fridges

- Slushie machines

- Under counter freezers

- Under counter fridges

- Upright freezers

- Upright fridges

- Other

- Restaurant furniture

- Shop all equipment

- Customers

- FAQs

- Resources

- About Us

Share

Best commercial meat slicers: Buyer's guide

article

What’s inside this buyer’s guide

- Introduction

- How to choose the right meat slicer for your needs?

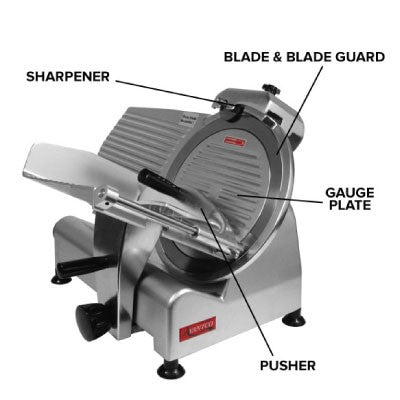

- Parts of a meat slicer

- Other features to consider

- Safety features

- Best commercial meat slicers

- Used commercial meat slicers — worth considering?

- Frequently asked questions

- Meat slicer glossary

- Keep your cash, use ours!

The humble commercial meat slicer may not take the limelight in your kitchen but is sure to add extra precision to your cuisines with its razor-sharp, consistent performance.

If your food service establishment handles a substantial amount of meat, a good meat slicer machine can considerably improve your kitchen’s productivity.

Most models can also slice vegetables, bread, fruit and cheese with precision.

However, choosing the best commercial meat slicer might is not easy, considering the countless models, prices, and features—each claiming to be the best— available in the market.

This commercial meat slicer buying guide covers all the vital information you need to slice through the confusion and make the right choice.

How to choose the right meat slicer for your needs?

When choosing a commercial meat slicer, also known as a deli slicer, you need to consider what and how much you intend to slice with the equipment.

If you plan to slice vegetables, bread or cheese along with meat, you will need to opt for a more versatile (and more expensive) model than if your purpose is only to slice meat.

Several variations of commercial meat cutting machines are available in the market, and you should pick a model that will serve your particular purpose effectively.

Depending on their capacity and performance, meat or deli slicer machines are categorised under three different types.

Entry-level

The entry-level commercial meat slicers are designed for light-duty applications and can perform for a maximum of one to two hours a day.

These models are operated manually and are safe for back-of-house as well as front-of-house applications in smaller food services like cafés, delis and specialty restaurants with less demand.

The entry-level models are typically compact and house a motor in the range of 0.06hp to 0.3hp, complete with a 9-inch to 10-inch blade.

These are also cheaper and easy to store but lack advanced safety features, power and versatility.

They will work fine if you need to slice only meat at room temperature in limited quantities but are not suitable for cutting frozen items or cheese.

Mid-level

Mid-level commercial meat slicer machines bring more power and efficiency to the table compared to entry-level models.

They can operate for two to three hours a day and are suitable for medium-duty applications in cafeterias, restaurants and delis.

These can be either manual or automatic, giving more flexibility than entry-level machines.

They come with a motor of around 0.3hp to 0.5hp, and their blade size typically is in the range of 10 inches to 12 inches.

These are more expensive than the entry-level models and pack more safety and convenience features.

While they can slice cheese for 1-2 hours per day, these are particularly designed for vegetable and meat slicing.

Premium

The premium commercial electric meat slicers are heavy-duty models engineered for continuous use in larger restaurants, butcher shops and other food services.

These models often combine top-of-the-line safety and convenience features, delivering seamless operation with maximum precision.

They typically house a 12 to 14-inch blade and at least a 0.5hp motor.

They can be manual or automatic, depending on the particular make and model.

Premium slicers are naturally more expensive than the previous two, and can continuously slice not only frozen meat, veggies, and bread but also cheese.

Apart from the three major categories discussed, there are also specialty slicers that are particularly used for cutting prosciutto or paper-thin slices of meat.

Parts of a meat slicer

All commercial meat slicer machines typically come with the following common parts.

Product table

Also known as the product tray or carriage, it is a part of the slicer where you place the meat, vegetable or cheese for slicing.

The tray is usually grooved and tilted at an angle towards the blade for easy sliding of the content placed on it.

Pusher

The pusher or meat grip is the slicer component that remains attached to the product table and helps to hold the food in the right place during slicing.

This part may or may not be removable, depending on the make and model of the deli slicer.

Gauge plate

It is the plate that surrounds the knife within the slicer.

When you adjust the thickness-control knob, this part moves and allows the adjustment.

Blade and blade guard

The blade is certainly the most important part of the meat cutting machine.

It might be permanently fixed or removable with a special tool depending on the model of the slicer.

The blade guard, also known as the ring guard, is the component that protects the blade and may be removable to various degrees for cleaning.

Other features to consider

Understanding your requirements is the first step to getting the best meat slicer for your kitchen.

Next, consider the following features to find a machine that fits all your requirements.

Horsepower

The more horsepower, the more powerful the machine.

So, if you intend to use the meat slicer frequently and for a longer duration, get a model with higher horsepower.

Typically, meat slicer motors are 0.06 to 0.5hp, and premium models carry the most powerful motors.

Blade size

The size of the blade determines the amount of food a meat cutting machine can slice.

The mid-level and premium models designed for medium and heavy-duty use generally house larger blades ranging between 12 inches and 14 inches in size.

The light-duty models, on the other hand, have a typical blade size of around 9 inches to 10 inches.

Product tray size

The size of the product tray decides the diameter of the food the machine can hold and slice.

This tray is generally 7.5 inches to 12 inches in diameter.

If you intend to slice food that’s more than 12 inches, you need to look for a model with a suitable tray size.

Manual vs automatic

In an automatic deli slicer, a motor moves the product tray back and forth.

This enables not only quick and continuous slicing of the food placed on the tray but also needs minimum supervision.

Most automatic slicers might also be used manually as per need.

Pure manual slicers, on the contrary, needs more supervision and work better only for low-volume requirements.

Belt-driven vs gear-drive

Commercial deli meat slicers can be either belt-driven or gear-driven.

In a belt-driven slicer, a belt is used to power the blade that slices the food.

In a gear-driven model, mechanical gears are fitted with the motor shaft and blade for slicing the food.

Gear-driven models can handle heavier workloads for less maintenance, but in case of a breakdown, repairing can be more expensive compared to a belt-driven model.

Ease of cleaning

Proper cleaning and sanitising of the slicer are essential for food hygiene and the longevity of the equipment.

Look for a model that can be dismantled easily to clean the different parts.

Some models come with specialised legs that let you easily prop up the machine and clean the area underneath.

Scales

Scales are used to measure the amount of meat being sliced. In commercial setups, this feature ensures that the correct amount of food is being sliced as per the requirements.

Safety features

Safety features are extremely important for a commercial meat slicer.

The mid-range and premium models from prominent brands combine multiple safety features for safe operation.

However, there are comparatively fewer safety features in entry-level models, and they might need more careful handling.

Consider the following safety features while choosing a meat slicer.

Knife/blade guard

An essential safety feature for all commercial meat slicing machines.

The knife or blade guard covers the spinning blade and ensures minimum exposure, reducing the chance of accidents.

It might be removable in some models.

No-volt release

The no-volt release system is designed to prevent the slicer from automatically re-starting following a power failure.

The user will need to push a button manually once the power is restored to get it started.

Gauge plate interlock

A simple yet highly effective safety feature that is designed to prevent the machine from operating unless the gauge plate is in a safe position.

This interlocking system requires you to set the gauge plate at ‘zero’ before removing the product tray.

Automatic switch-off

Available in some meat slicer models, this feature is designed to automatically turn off the slicer after a certain period of inactivity or under certain conditions like overheating.

It prevents accidental injury from an unattended running slicer and also saves electricity.

Best commercial meat slicers

Birko

Birko Electrics is an Australian company with a rich history that spans over 50 years.

They manufacture a range of commercial kitchen equipment, including but not limited to grills, fryers, toasters, ovens, slicers and filters.

Birko is a trusted partner in many Australian commercial kitchens.

Birko slicers are known for their high quality, durability and are capable of slicing a variety of meats with maximum precision.

Their slicers are designed specifically for small and medium commercial operations.

The slicer range offers two models – Slicer 1005100 (250mm) and Slicer 1005101 (300mm).

The more compact model with 150W and 250mm blade diameter has a slicing thickness of 1-12mm.

The larger model has 250W and a blade diameter of 300mm.

This meat cutting machine has a slicing thickness of 0-15mm.

Noaw

Founded in 1972, Noaw, an Italian company, has since grown into a globally acclaimed manufacturer of commercial meat slicers.

The brand is known for its commitment to innovation and quality.

Their slicer range covers gravity-fed slicers, automatic slicers, straight-feed slicers, vertical slicers and the iconic flywheel slicers – providing an extensive range of options for food services.

Noaw's slicers are famous for their ergonomic design, superior precision, and lasting durability.

The company's NS350HDG—a gravity-feed gear-driven slicer—is one of its star performers with 210 RPM blade speed and 350 mm blade diameter, renowned for managing heavy workloads with ease.

Equally popular is the Noaw NS250, a manual, belt-driven slicer that excels in small to medium operations.

Hobart

Hobart, a giant in the commercial food equipment industry, started its journey in 1897 in Troy, Ohio, and has since set the benchmark for commercial kitchen appliances.

The company’s product range covers steamers to dishwashers, mixers, and the list goes on.

Its meat slicers are globally renowned for their reliability, durability, and precision.

These are designed to slice everything from delicate meats and cheeses to dense products, all with the ease and speed that busy commercial kitchens require.

Hobart meat and deli slicers are pricey, but they are worth every penny.

The Hobart Edge manual gravity feed slicer, featuring a 305 mm knife diameter, is a popular choice for medium-duty applications.

It’s known for durability and easy maintenance.

The HS9 is another favourite, offering more advanced features like automatic slicing and programmable controls, which are ideal for heavy-duty applications.

Brice

Established in 1939, Brice Australia is a revered name in the food equipment industry, recognised for its commitment to quality and top-notch service.

With an extensive range of products, this 100% Australian-owned company represents some of the world’s most prestigious commercial kitchen equipment brands.

Renowned for robust construction and precise slicing, Brice's meat slicers are an industry favourite, equipped to handle the demands of Aussie butcheries and delis with efficiency.

The collection covers a suite of slicer types, including gear-driven, belt-driven, semi-automatic, fully automatic, and vertical meat slicers.

The Brice 300IX is a manual, gravity-feed slicer designed for heavy-duty operations in medium to large kitchens, known for its convenience and efficiency in handling meat of all kinds.

For heavier demands, the Brice L series flatbed gear-driven meat slicer stands out.

With its stainless steel-anodised aluminium body, built-in dual action sharpener and large-capacity meat table, it can manage all high-volume demands with maximum efficiency.

Anvil

Anvil, established in 1966, is one of South Africa’s most recognised commercial food service equipment manufacturers and suppliers.

The brand has a prominent presence in over 30 countries across the globe.

Anvil meat slicers are known for high-quality materials, durability and ease of use.

Plus, they are backed by a comprehensive warranty.

In addition to their deli meat slicers, Anvil also offers a variety of other products for the food service industry, including ovens, grills, and fryers.

The company provides reliable equipment that can endure the demands of a busy kitchen.

Among the popular models is the Anvil SLR5010, featuring a 0.32kW motor and a 250mm slicing blade with a built-in sharpener.

It is ideal for medium workloads of smaller restaurants and takeaways.

For heavy-duty commercial needs, the Anvil SLR5312 electric meat slicer features a double platform design ideal for high production output in supermarkets and butchers.

It comes with a 305mm blade and a 0.42kW motor.

Used commercial meat slicers — worth considering?

Spending thousands of dollars on a new commercial meat slicer can put a strain on your budget and cash flow.

If you’d prefer not to invest a lot of money in a meat slicer, a cheaper, pre-owned appliance might be the solution you’re looking for.

SilverChef’s range of ‘Certified Used’ commercial equipment is mostly ex-rental equipment sourced from businesses we know and trust.

The equipment is typically less than two-and-a-half years old, has been fully refurbished by us, and is backed by a three-month parts-and-labour warranty.

Considering the effective, or useful, life of a commercial meat slicer is around 5 to 10 years, you can be sure our Certified Used commercial meat slicers have plenty of life left in it.

You can either buy or finance the ‘Certified Used’ (and clearance) equipment on our website. (We’re one of the few financiers, if not the only one, in Australia that funds second-hand commercial kitchen equipment.)

Read more about ‘Certified Used’ equipment

Frequently asked questions

Where can I purchase a high-quality commercial meat slicer for sale in Australia?

In Australia, there are several places where you can purchase a high-quality commercial meat slicer.

E-commerce platforms like Amazon and eBay might be a good place to start, but if you are looking for mid to heavy-duty models, we suggest checking out the stores of renowned commercial kitchen equipment suppliers close to your area.

If you are looking for a used commercial meat slicer or want to get a new one on affordable monthly rent, check out the collection on our website.

How can I ensure the safe use of a meat slicer in my commercial kitchen?

Ensuring the safe use of a deli meat slicer in your commercial kitchen involves several important steps.

Make sure all staff who will be using the meat slicer are properly trained in its operation.

They should understand how to adjust the thickness, start and stop the machine, and feed the product safely.

Keeping the area around the slicer clear of obstructions, ensuring all safety features are working properly, right handling of the blade and wearing cut-resistant gloves while operating are important to ensure safety.

Always follow the manufacturer's instructions for operating your slicer.

How do I maintain a commercial meat slicer for my restaurant in Australia?

Maintaining a commercial deli meat slicer is essential for ensuring its longevity, effectiveness, and safety.

To keep it in the best condition, clean and sanitise the slicer with the right products after each use.

Follow the proper process of dismantling and reassembling the equipment after each cleaning cycle, as indicated in the manufacturer’s instructions.

Lubricate the sliding parts and sharpen the blades at regular intervals. Also, inspect regularly for any signs of wear and tear and arrange a professional for servicing as needed.

Commercial meat slicer glossary

Built-in sharpener

Some slicers have a built-in device for sharpening the blade, ensuring uninterrupted performance for a longer period.

Continuous duty

A term indicating the slicer is designed to operate for extended periods without needing a break to cool down.

Gravity feed slicer

A type of slicer where the carriage is angled, allowing gravity to assist in moving the food item towards the blade.

Intermittent duty

Slicers with this designation are meant to be used for a period and then allowed to rest and cool down to prevent overheating.

Non-slip feet

Many slicers have non-slip feet to keep the slicer stable and secure during operation.

Overload protection

A feature that prevents the motor from overheating and burning out.

It may automatically shut off the slicer if the motor gets too hot.

Serrated blade

A type of blade that has a toothed or saw-like edge.

Serrated blades are ideal for slicing through crusty bread or tough-skinned fruits and vegetables.

Smooth blade

This type of blade is ideal for slicing meats and cheeses.

It provides clean and smooth cuts.

Safety interlock

A feature that prevents the slicer from operating under certain conditions, like when the gauge plate is open or when certain parts are removed.

Sealed buttons

Buttons that are sealed to prevent water, food particles, and other contaminants from getting inside the machine.

Vertical slicer

A slicer where the food item is held vertically against the blade.

These are often used for slicing heavier items like cheese.

Keep your cash. Use ours!

We hope this guide has helped you better understand what you need to look for in a commercial meat slicer and how to choose the right model for your needs. If you want to know more, you can always reach out to the SilverChef team.

Hospitality equipment can be expensive and paying for it outright can put pressure on your business’s cash flow.

Our finance solutions allow you to get the equipment you want now and to pay for it in small, regular amounts out of the revenue it generates for you.

Rent–Try–Buy® not only helps you maintain your cash flow, it gives you unrivalled flexibility to adapt your equipment to the changing needs of your business.

You can upgrade or buy the equipment at any time or, after 12 months, return or continue renting it.

If you decide to buy the equipment, we’ll give you back 75% of the net rent you paid in the first year and 25% of any rental payments thereafter — to put toward the purchase price.